generator installation guidelines

SHUNT TRIP / EMERGENCY SHUT OFF (Section 509.2.1)

-

A remote electrical shunt trip/switch shall be provided where any of the following conditions occur:

In new or remodeled structures where the main power disconnect switch is located in the interior of a building

In new or remodeled structures where the main power disconnect switch is inaccessible to fire department personnel due to location or to climatic conditions

In new or remodeled structures equipped with multiple eletrical sources, such as fuel cells, ESS, generators or solar photovoltaic systems.

In existing structures where a new electrical power source is provided, such as fuel cells, ESS, generators or solar photovoltaic systems.

-

Each electrical shunt trip/switch shall have an approved, permanently mounted, weatherproof sign indicating the power source it controls.

For example, it might read: “GENERATOR SHUNT TRIP SWITCH”

-

The remote main power electrical shunt trip/switch shall be hard wired to all power sources.

The electrical shunt trip/switch shall be installed on the exterior of the building in a location approved by the Fire Code Official and protected from the elements.

The shunt trip should be installed within 3 feet of the main electrical disconnect and clearly visible for emergency response crews.

VEHICLE IMPACT PROTECTION

-

Vehicle impact protection required by this code shall be provided by posts that comply with Section 312.2 or by other approved physical barriers that comply with Section 312.3.

-

Guard posts shall comply with the following requirements:

Constructed of steel not less than 4 inches (102 mm) in diameter and concrete filled.

Spaced not more than 4 feet (1219 mm) between posts on center.

Set not less than 3 feet (914 mm) deep in a concrete footing of not less than a 15-inch (381 mm) diameter.

Set with the top of the posts not less than 3 feet (914 mm) above ground.

Located not less than 3 feet (914 mm) from the projected object.

-

Barriers, other than posts specified in Section 312.2, that are designed to resist, deflect or visually deter vehicular impact commensurate with an anticipated impact scenario shall be permitted where approved.

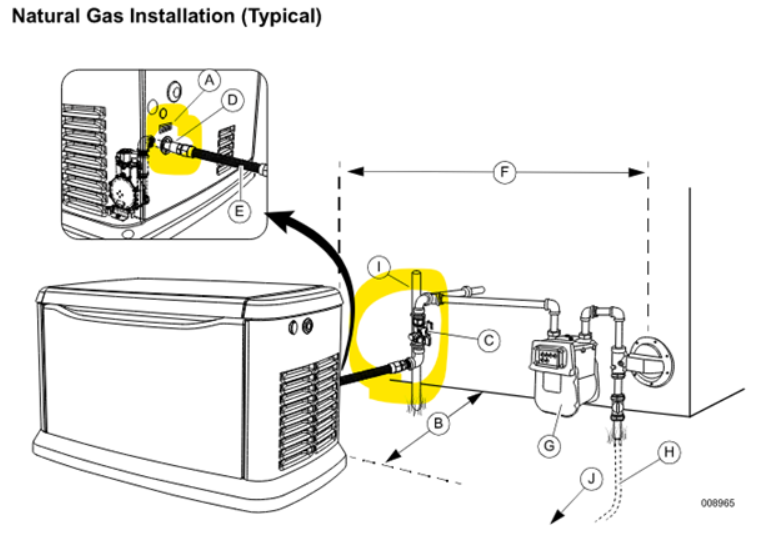

GAS LINE PROTECTION

-

Gas piping for residential generator’s must be protected from heavy snow load and falling ice. Gas piping and appurtenances are not permitted to be installed on the snow shed side of the roof.

Section 1203.7 Protection from horizontal impact. Fuel piping to generators shall be protected from the damage where underground fuel piping extends above the ground and is located in an area subject to the horizontal movement of snow. The barrier or method of protection shall be approved by the fire code official.

-

605.8 Meters and equipment. Above-ground meters, regulators, secondary regulators and piping supplying fuel to fuel-fired appliances shall be protected in accordance with the following:

New above-ground meters, regulators, secondary regulators and piping supplying fuel to fuel-fired appliances shall be protected in accordance with Section 605.8.1.

Existing above-ground meters, regulators, secondary regulators and piping supplying fuel to fuel-fired appliances shall be protected in accordance with Section 605.8.1 when required by the fire code official.

-

Above-ground meters, regulators, secondary regulator and piping supplying fuel to fuel-fired appliances shall comply with the following:

Meters, regulators and piping subject to vehicular damage shall be protected by a barrier in accordance with Section 312.

New meter installations shall be as close as practical to the building wall and located at the gable end of the building or under an engineered deck.

A protective cover shall be installed over meters, regulators and piping. The protective cover shall comply with the following:

3.1. The protective cover shall be capable of supporting the design snow load over the meter and piping assembly.

3.2 The protective cover shall meet the approval by the fuel supplier.

3.3. The protective cover shall allow ready access to the gas meter and piping.

3.4. Where the protective cover encloses the meter and piping assembly on all sides, an approved removable panel shall be provided which can be removed without the use of tools at the front of the protective cover. Exception: The Southwest Gas standard is an acceptable alternative for the protective cover, provided the cover also complies with Item 3.4.

Meters, regulators and piping shall be protected from horizontal slide or shift of snow and ice where underground piping extends above ground on a sloping grade or in a location where snow and ice can build up and encroach laterally into the protective cover. The barrier or method of protection shall be approved by the fire code official.

-

Prior to continued use and service of tanks, meters, regulators and piping shall be inspected and approved by the fire code official after any of the following events:

When service is interrupted or temporarily discontinued, because of a hazardous condition.

Change in size or type of service.

Replacement or repair of a tank, meter, regulator, valve or other exterior component, that is not part of routine maintenance for the gas supplier.

Relocation of exterior service equipment or piping.

Damage to buildings, tanks, meters, piping or exterior components to the extent that the servicing utility, fire department or building department determines the service to be potentially hazardous.

The inspection shall occur prior to refilling the tank or placing the equipment back in operation. Routine refilling of a tank and routine maintenance. of interior appliances does not require this inspection and approval.

DIESEL GENERATORS

NFPA 704 Placards must be displayed indicating associated hazards.

Provides a simple, readily recognized, easily understood system for identifying the specific hazards of a material and the severity of the hazard that would occur during an emergency response in a fixed facility.

The system addresses the health, flammability, instability, and special hazards presented from short-term, acute exposures that could occur because of a fire, spill, or similar emergency involving the materials present.